when you sterilize surgical instruments you don’t want ratchets

When You Sterilize Surgical Instruments, You Don’t Want Ratchets: Here’s Why

Proper sterilization of surgical instruments is a cornerstone of maintaining patient safety and preventing infections in medical settings. However, sterilizing instruments with ratchets presents unique challenges that many healthcare professionals may not immediately recognize. In this blog, we’ll explore why you don’t want ratchets when sterilize surgical instruments, the risks involved, and best practices to ensure optimal sterilization.

Understanding Ratchets in Surgical Instruments

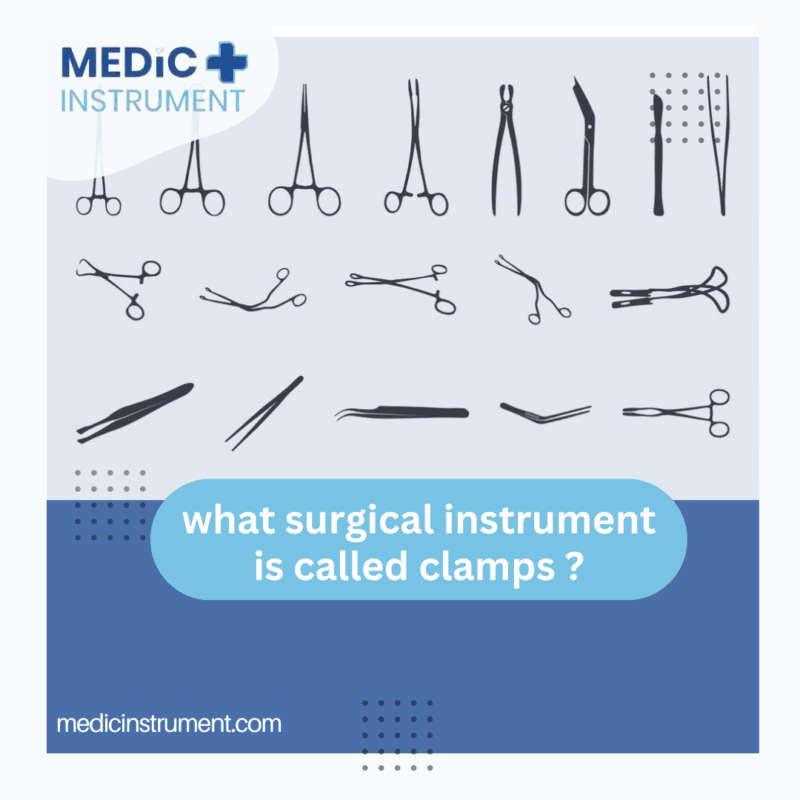

Ratchets are locking mechanisms commonly found in surgical instruments like hemostats, needle holders, and certain types of clamps. These mechanisms allow the instrument to lock into place, providing surgeons with precision and stability during procedures. While ratchets are invaluable in surgery, they can complicate the sterilization process due to their intricate design.

Why Ratchets Pose Challenges During Sterilization

Sterilizing surgical instruments with ratchets can be problematic for several reasons:

- Hard-to-Reach Areas

Ratchets consist of small, interlocking components that create hidden spaces. These crevices can trap biological material such as blood, tissue, or other debris, making it difficult to fully clean and sterilize the instrument. Residual matter in these areas can lead to the growth of harmful bacteria and compromise the sterility of the instrument. - Inadequate Sterilant Penetration

Sterilization methods, whether they involve steam, ethylene oxide, or hydrogen peroxide gas plasma, rely on the ability of the sterilant to penetrate all surfaces of an instrument. Closed ratchets or partially locked mechanisms can block the sterilant from reaching every surface, leaving certain areas unsterilized. - Increased Risk of Cross-Contamination

If ratchets are not thoroughly cleaned and sterilized, they can serve as a source of cross-contamination during surgery. This poses a significant risk to patient safety, as it can lead to post-surgical infections, delayed healing, or even life-threatening complications. - Wear and Tear on Instruments

Repeated sterilization of ratchets can also lead to wear and tear on the locking mechanism. Over time, the ratchet may become loose or fail to lock properly, rendering the instrument ineffective or unsafe for use.

Best Practices for Sterilizing Instruments with Ratchets

Despite the challenges, ratcheted surgical instruments can be safely sterilized with the right approach. Here are some best practices to ensure complete sterilization:

- Proper Pre-Cleaning

Thorough cleaning is the first step in the sterilization process. Use enzymatic detergents to break down organic material and pay special attention to the ratchet area. Brushes or specialized cleaning tools can help dislodge debris from hard-to-reach spaces. - Unlock Ratchets Before Sterilization

Always ensure that ratchets are fully open before placing instruments in the sterilizer. This allows the sterilant to reach all parts of the instrument, reducing the risk of contamination. - Ultrasonic Cleaning

For an added layer of cleaning, use ultrasonic cleaners. These devices use high-frequency sound waves to create microscopic bubbles that can reach areas that manual cleaning might miss, including the intricate spaces within ratchets. - Inspection Before Sterilization

After cleaning and before sterilization, inspect instruments for visible debris or damage. Instruments with worn-out ratchets should be repaired or replaced to ensure their functionality and sterility. - Use Sterilization Trays

Organize instruments in sterilization trays in a way that prevents overcrowding. Ensure ratcheted instruments are placed in the tray with their ratchets fully open and unobstructed. - Document and Follow Protocols

Adhering to sterilization protocols and documenting the process ensures accountability and consistency. Regular audits of sterilization procedures can help identify areas for improvement and ensure compliance with healthcare standards.

Advanced Sterilization Methods

In addition to traditional sterilization techniques, advancements in sterilization technology can improve the efficacy of sterilize ratcheted instruments:

- Automated Washer-Disinfectors

These machines provide consistent cleaning and sterilization cycles, ensuring thorough cleaning of complex instruments like those with ratchets. - High-Pressure Steam Sterilization

Autoclaves with dynamic air removal cycles can ensure that steam penetrates all parts of the instrument, even in areas around the ratchets. - Single-Use Instruments

For specific procedures, consider using single-use ratcheted instruments. While not suitable for all cases, they eliminate the need for sterilization altogether, reducing the risk of contamination.

Why Sterilization Matters

Ensuring the sterility of surgical instruments is a critical part of infection control in healthcare. Contaminated instruments can introduce harmful pathogens into the sterile environment of the operating room, leading to severe complications for patients and legal or reputational consequences for healthcare facilities. Properly addressing the challenges associated with ratcheted instruments demonstrates a commitment to patient safety and high-quality care.

Conclusion

When sterilize surgical instruments, you don’t want ratchets—or rather, you don’t want ratchets to remain closed during the sterilization process. The intricate design of ratchets poses unique challenges, but with proper cleaning, sterilization techniques, and adherence to best practices, these challenges can be effectively addressed. By ensuring that ratcheted instruments are clean, open, and properly maintained, healthcare providers can enhance patient safety and reduce the risk of surgical infections.

For healthcare professionals and facilities, investing in the right tools, training, and protocols is essential for maintaining the highest standards of sterilization. Remember, a clean and sterile instrument is not just a requirement—it’s a responsibility.